MRI-Compatible Robotics

Client

AiM Medical Robotics

Practice Areas

Challenge

AiM Medical Robotics required a portable robotic system to perform neurosurgery simultaneous with magnetic resonance imaging (MRI). MRI relies on incredibly strong magnetic fields to produce detailed images of the inside of the human body. These strong magnetic fields prohibit the use of ferromagnetic materials that are found in typical robotic hardware. Furthermore, MRI systems feature a small bore around the patient table which severely restricts the form factor of potential robots. Triple Ring overcame these hurdles by employing first-principles thinking and creative engineering.

Outcomes

The partnership led to an innovative prototype design with 4 degrees of freedom that served as the basis of AiM Medical Robotics’ industry-first robotics platform.

Triple Ring Value Proposition

- Experience in designing multi-axis robots for multiple applications

- Deep expertise in the physics of MRI

- Demonstrated capabilities in designing MRI-compatible systems and components

- Rapid design, prototyping, and production to meet tight timelines and funding milestones

MRI-Compatible Robotics

Challenge

AiM Medical Robotics required a portable robotic system to perform neurosurgery simultaneous with magnetic resonance imaging (MRI). MRI relies on incredibly strong magnetic fields to produce detailed images of the inside of the human body. These strong magnetic fields prohibit the use of ferromagnetic materials that are found in typical robotic hardware. Furthermore, MRI systems feature a small bore around the patient table which severely restricts the form factor of potential robots. Triple Ring overcame these hurdles by employing first-principles thinking and creative engineering.

Outcomes

The partnership led to an innovative prototype design with 4 degrees of freedom that served as the basis of AiM Medical Robotics’ industry-first robotics platform.

Triple Ring Value Proposition

- Experience in designing multi-axis robots for multiple applications

- Deep expertise in the physics of MRI

- Demonstrated capabilities in designing MRI-compatible systems and components

- Rapid design, prototyping, and production to meet tight timelines and funding milestones

Client

AiM Medical Robotics

Practice Areas

Background

AiM Medical Robotics chose to work with Triple Ring due to our deep scientific knowledge of the principles of MRI, our extensive experience engineering complex robotics, and our ability to develop creative solutions to complicated, constrained problems. Because of this, Triple Ring was able to deliver a design for AiM Medical Robotics that met the stringent requirements of MRI-compatibility.

Upright Radiation Therapy

Client

Leo Cancer Care

Practice Areas

Challenge

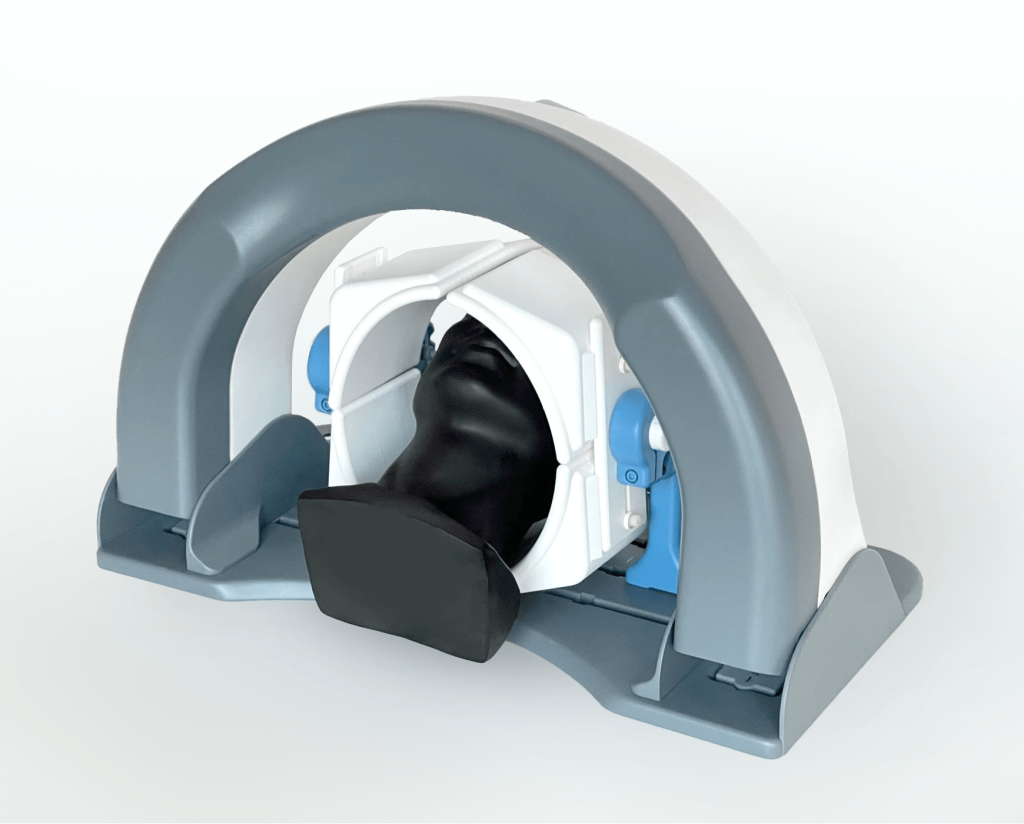

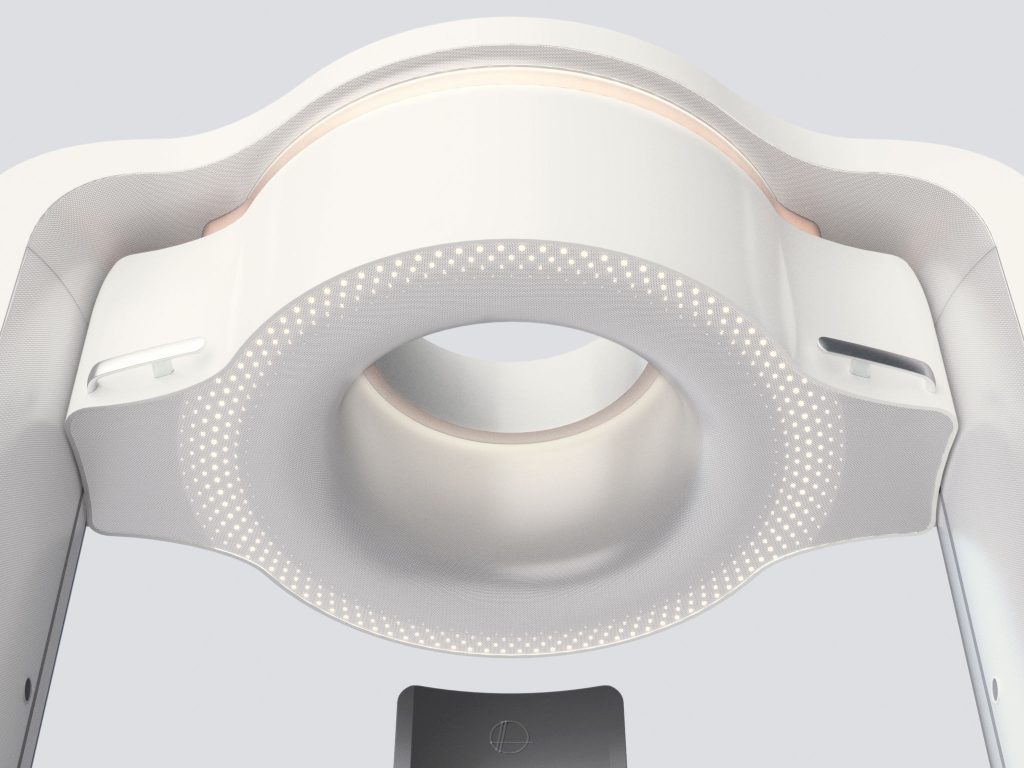

Leo Cancer Care partnered with Triple Ring Technologies to design a computed tomography (CT) imaging system for a novel radiation therapy concept enabling better patient outcomes and improved patient experience. Leo Cancer Care is a bold innovator in radiation therapy, developing breakthrough products that treat patients in a more natural, seated position. The system images and positions the patient for radiotherapy in one device while the patient is upright, improving accuracy while increasing comfort and lowering stress – all contributing factors to better outcomes. Triple Ring collaborated with Leo Cancer to design a gantry and CT scanner enabling CT scans of patients in upright and lying down position. This concept is central to Leo Cancer’s platform, making large rotating gantries for the radiotherapy source obsolete, and enabling a fixed beam, slow patient rotation strategy. Leo Cancer and Triple Ring together overcame multiple design and technical challenges to transform this novel concept into a safe, accurate, and patient-centric platform.

Outcomes

The Leo Cancer Care and Triple Ring collaboration led to the creation of an innovative gantry design that featured upright radiation therapy as a new standard of care.

Triple Ring Value Proposition

- Experience designing large multi-axis robotics

- Deep expertise in the physics of radiotherapy delivery devices

- Mechanical design of robust and reliable capital equipment to ISO13485 standards

- Advanced simulation and modeling to streamline system design, development, and test

- Shared sense of urgency to meet aggressive schedules and assure funding milestones

Upright Radiation Therapy

Challenge

Leo Cancer Care partnered with Triple Ring Technologies to design a computed tomography (CT) imaging system for a novel radiation therapy concept enabling better patient outcomes and improved patient experience. Leo Cancer Care is a bold innovator in radiation therapy, developing breakthrough products that treat patients in a more natural, seated position. The system images and positions the patient for radiotherapy in one device while the patient is upright, improving accuracy while increasing comfort and lowering stress – all contributing factors to better outcomes. Triple Ring collaborated with Leo Cancer to design a gantry and CT scanner enabling CT scans of patients in upright and lying down position. This concept is central to Leo Cancer’s platform, making large rotating gantries for the radiotherapy source obsolete, and enabling a fixed beam, slow patient rotation strategy. Leo Cancer and Triple Ring together overcame multiple design and technical challenges to transform this novel concept into a safe, accurate, and patient-centric platform.

Outcomes

The Leo Cancer Care and Triple Ring collaboration led to the creation of an innovative gantry design that featured upright radiation therapy as a new standard of care.

Triple Ring Value Proposition

- Experience designing large multi-axis robotics

- Deep expertise in the physics of radiotherapy delivery devices

- Mechanical design of robust and reliable capital equipment to ISO13485 standards

- Advanced simulation and modeling to streamline system design, development, and test

- Shared sense of urgency to meet aggressive schedules and assure funding milestones

Client

Leo Cancer Care

Practice Areas

Background

Leo Cancer Care chose to work with Triple Ring because of our deep scientific knowledge in energy delivery and medical imaging matched with our proven success in building high-precision mechanical systems for clinical validation and market entry. Our work with Leo Cancer required close collaboration and tight communication to integrate multiple subsystems and produce a high quality, efficacious system.

Next-Generation Equine Imaging

Client

Prisma Imaging

Practice Areas

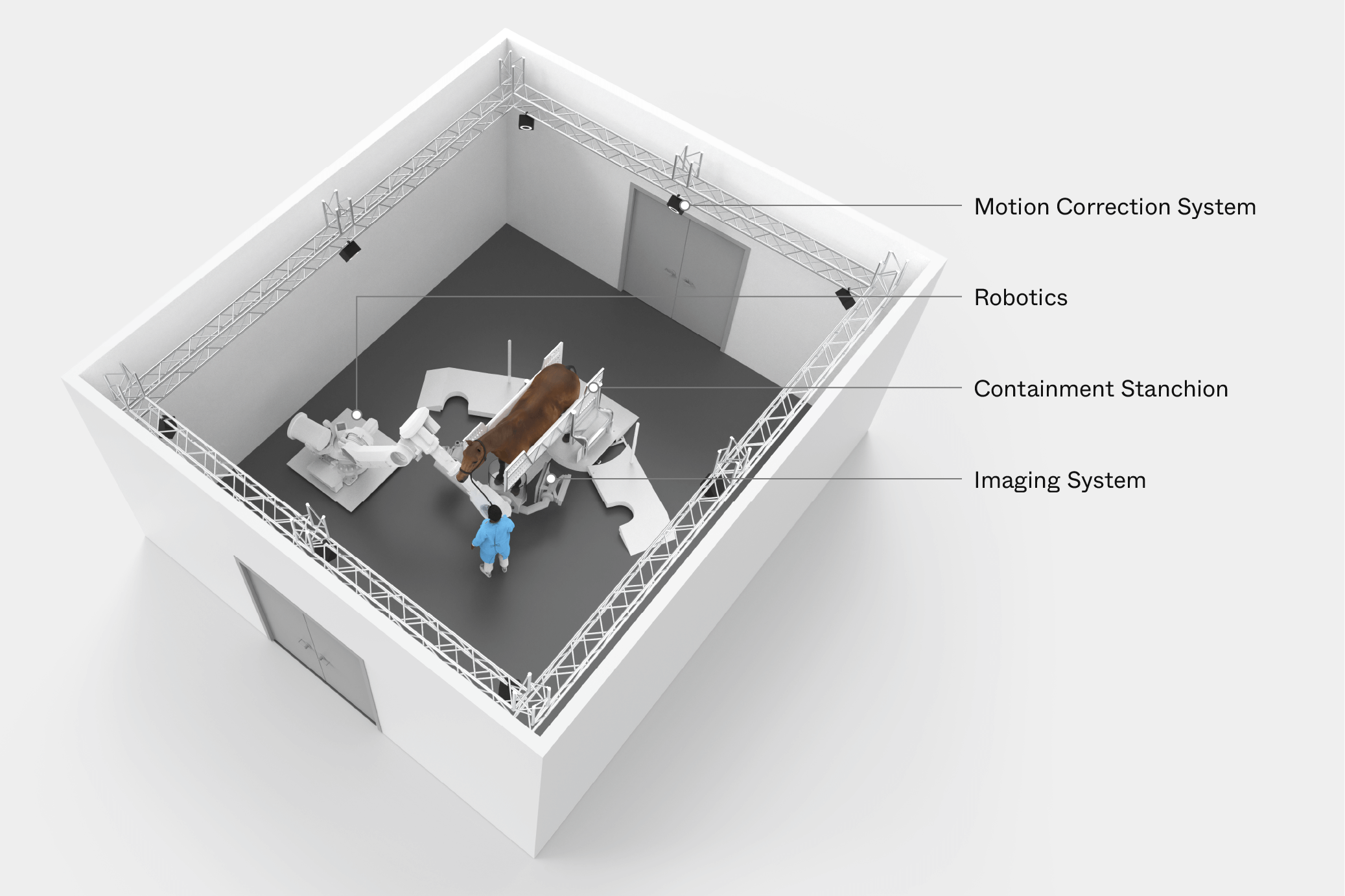

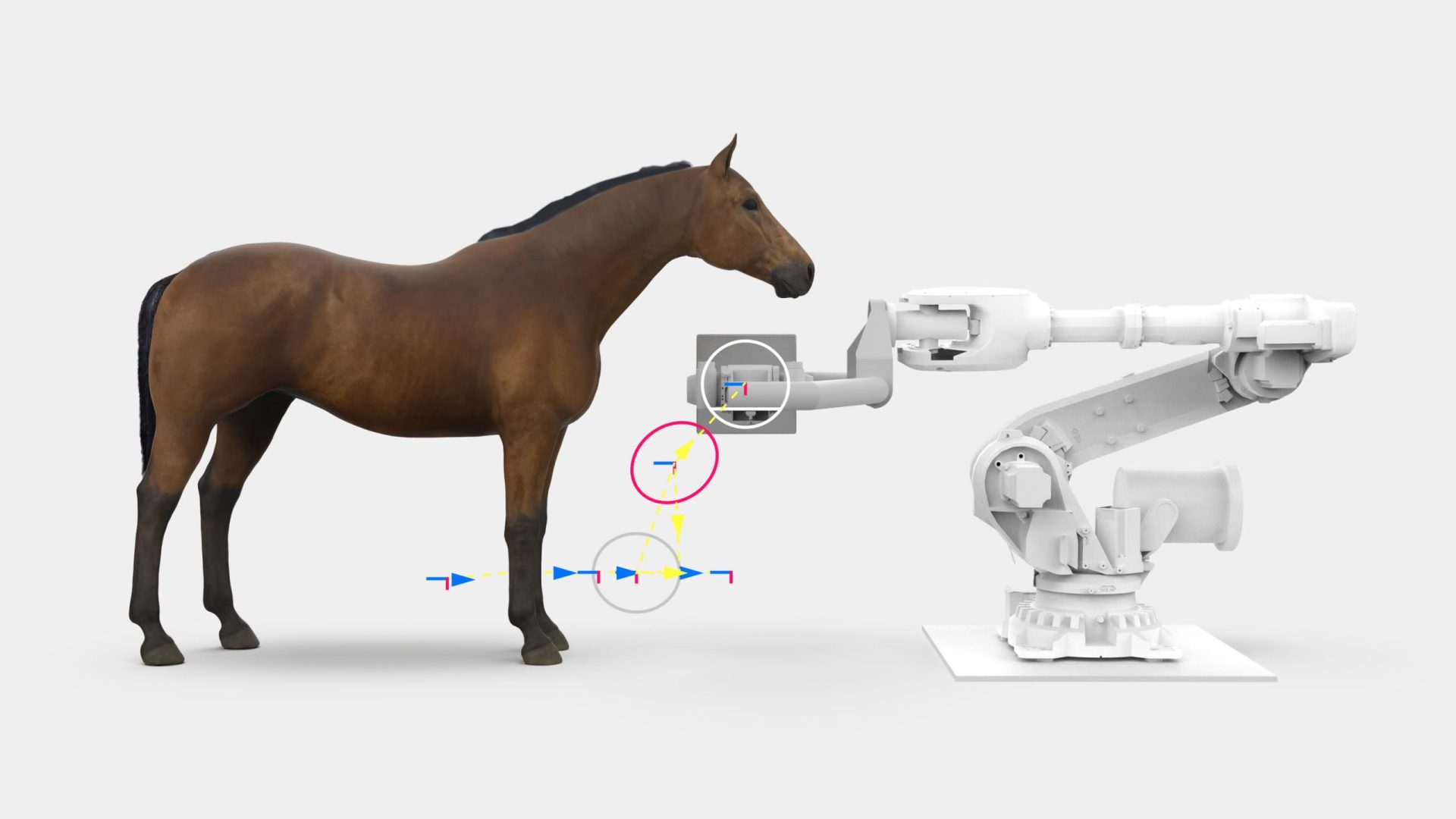

Challenge

Prisma Imaging partnered with Triple Ring Technologies to design, model, build, and test a functional prototype equine CT scanner for imaging on live animals in a veterinary clinic setting. Prisma Imaging invented a next generation large animal CT imaging system capable of generating high quality images in a vastly safer workflow for equine patients. This complex prototype system included a robotic gantry, motion capture and correction, X-ray imaging, radiation safety, and CT reconstruction engine. Such an extensive system required Triple Ring to leverage its cross-disciplinary expertise and implement a top-down systems engineering approach.

Outcomes

Triple Ring delivered a gantry-mounted CT imaging system, which enabled live-animal imaging at our headquarters in California on horses that were consciously sedated, not anesthetized. With its integrated cutting-edge motion tracking subsystem and correction algorithms, the system performed equivalently to current standard tabletop technology, even in the presence of natural patient movement. The X-ray system was supported by a robust mechanical subsystem and the combined motion/imaging system was carefully controlled by custom software/hardware.

Triple Ring Value Proposition

- Fully outsourced engineering services, from conception to assembly

- World class image reconstruction architecture and algorithm development capabilities

- Hands-on experience assembling complex hardware

- Deep expertise making complicated systems work, with deliberate and careful subsystem and integration testing

- Flexible and customizable lab space to support exotic applications, such as live-animal imaging

Next-Generation Equine Imaging

Challenge

Prisma Imaging partnered with Triple Ring Technologies to design, model, build, and test a functional prototype equine CT scanner for imaging on live animals in a veterinary clinic setting. Prisma Imaging invented a next generation large animal CT imaging system capable of generating high quality images in a vastly safer workflow for equine patients. This complex prototype system included a robotic gantry, motion capture and correction, X-ray imaging, radiation safety, and CT reconstruction engine. Such an extensive system required Triple Ring to leverage its cross-disciplinary expertise and implement a top-down systems engineering approach.

Outcomes

Triple Ring delivered a gantry-mounted CT imaging system, which enabled live-animal imaging at our headquarters in California on horses that were consciously sedated, not anesthetized. With its integrated cutting-edge motion tracking subsystem and correction algorithms, the system performed equivalently to current standard tabletop technology, even in the presence of natural patient movement. The X-ray system was supported by a robust mechanical subsystem and the combined motion/imaging system was carefully controlled by custom software/hardware.

Triple Ring Value Proposition

- Fully outsourced engineering services, from conception to assembly

- World class image reconstruction architecture and algorithm development capabilities

- Hands-on experience assembling complex hardware

- Deep expertise making complicated systems work, with deliberate and careful subsystem and integration testing

- Flexible and customizable lab space to support exotic applications, such as live-animal imaging

Client

Prisma Imaging

Practice Areas

Background

The system architecture developed and implemented by Triple Ring enabled Prisma’s system to be the only CT imaging technology that can access an equine patient’s entire anatomy without the use of anesthesia. Triple Ring was chosen for this aggressive project because of our deep technical knowledge in the diverse science and engineering disciplines required for success. No animals were harmed during testing.

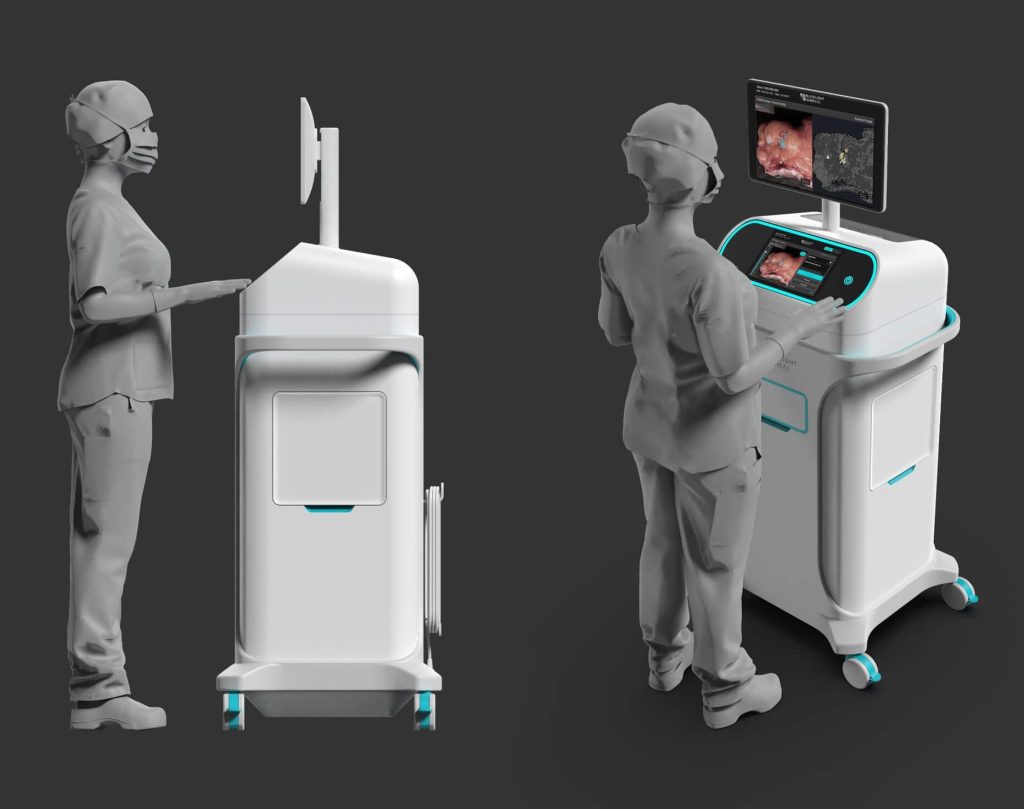

Intra-Operative Tissue Pathology

Client

BlackLight Surgical

Practice Areas

Challenges

Triple Ring Technologies was tasked with designing, integrating, testing, and delivering an innovative high-speed laser-based intra-operative biochemical imaging platform. The system leveraged picosecond pulsing laser technology for intra-operative tissue analysis. A user-centric design and workflow facilitated by machine learning successfully enabled real-time clinical decision making in the surgery suite.

Outcomes

Through Triple Ring’s proven product design and development process, Blacklight Surgical’s breakthrough imaging platform was built and delivered to support critical clinical studies. The system was designed to ISO13485 standards and fully documented within a Quality Management System (QMS) established by Triple Ring and transferred to Black Light Surgical.

Triple Ring Value Proposition

- Multidisciplinary science and engineering teams capable of design and development, integration, verification, test, and system build

- Included Engineering (Mechanical, Electrical, Software, Systems, BioMedical,and Test), Optical Science, Machine Learning, Industrial Design, Quality Management, and system assembly.

- Efficient design process featuring extensive modeling and complex simulations to derive requirements and guide prototyping.

Intra-Operative Tissue Pathology

Challenges

Triple Ring Technologies was tasked with designing, integrating, testing, and delivering an innovative high-speed laser-based intra-operative biochemical imaging platform. The system leveraged picosecond pulsing laser technology for intra-operative tissue analysis. A user-centric design and workflow facilitated by machine learning successfully enabled real-time clinical decision making in the surgery suite.

Outcomes

Through Triple Ring’s proven product design and development process, Blacklight Surgical’s breakthrough imaging platform was built and delivered to support critical clinical studies. The system was designed to ISO13485 standards and fully documented within a Quality Management System (QMS) established by Triple Ring and transferred to Black Light Surgical.

Triple Ring Value Proposition

- Multidisciplinary science and engineering teams capable of design and development, integration, verification, test, and system build

- Included Engineering (Mechanical, Electrical, Software, Systems, BioMedical,and Test), Optical Science, Machine Learning, Industrial Design, Quality Management, and system assembly.

- Efficient design process featuring extensive modeling and complex simulations to derive requirements and guide prototyping.

Client

BlackLight Surgical

Practice Areas

Background

BlackLight Surgical has harnessed the principles of Time-Resolved Laser Induced Fluorescence Spectroscopyto innovate within intra-operative pathology workflows. Collaborating with Triple Ring, they have created a new biochemical imaging platform that identifies margins between normal and disease tissues inside the surgical suite, in real-time, without labels. With our full teams of scientists, engineers, designers, and assembly technicians, Triple Ring was ideally suited to translate Blackight Surgical’s breakthrough technology to the clinic.

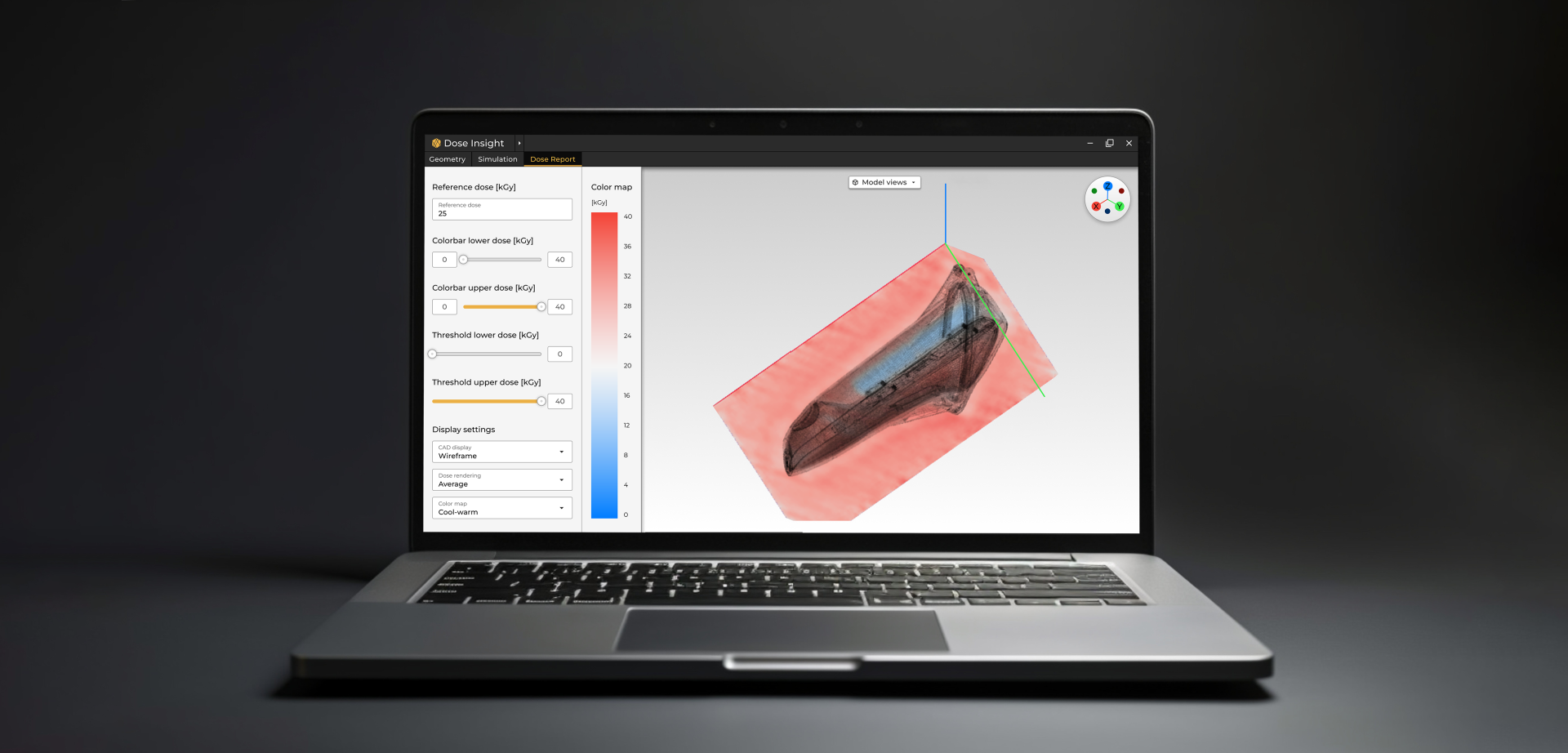

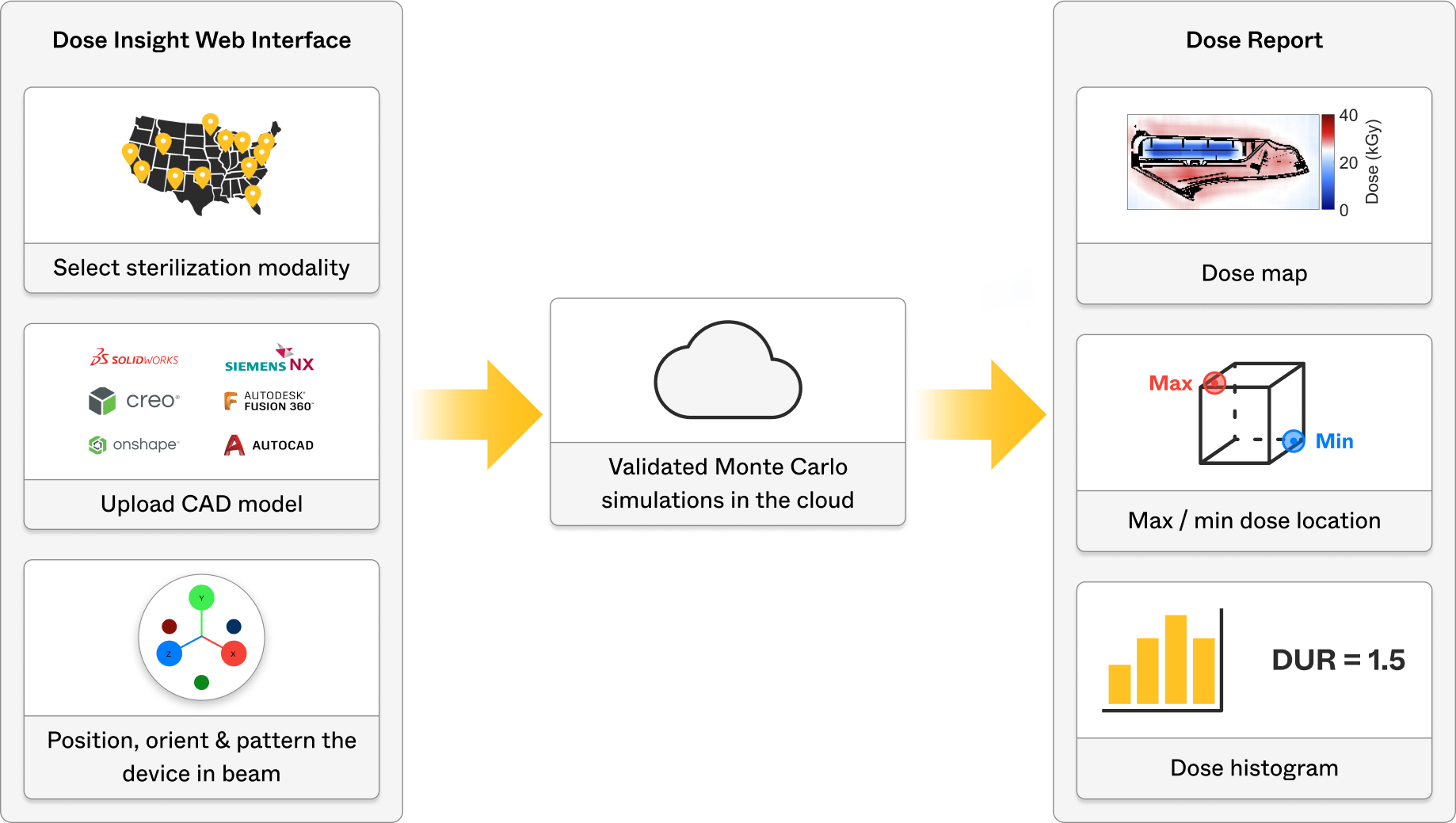

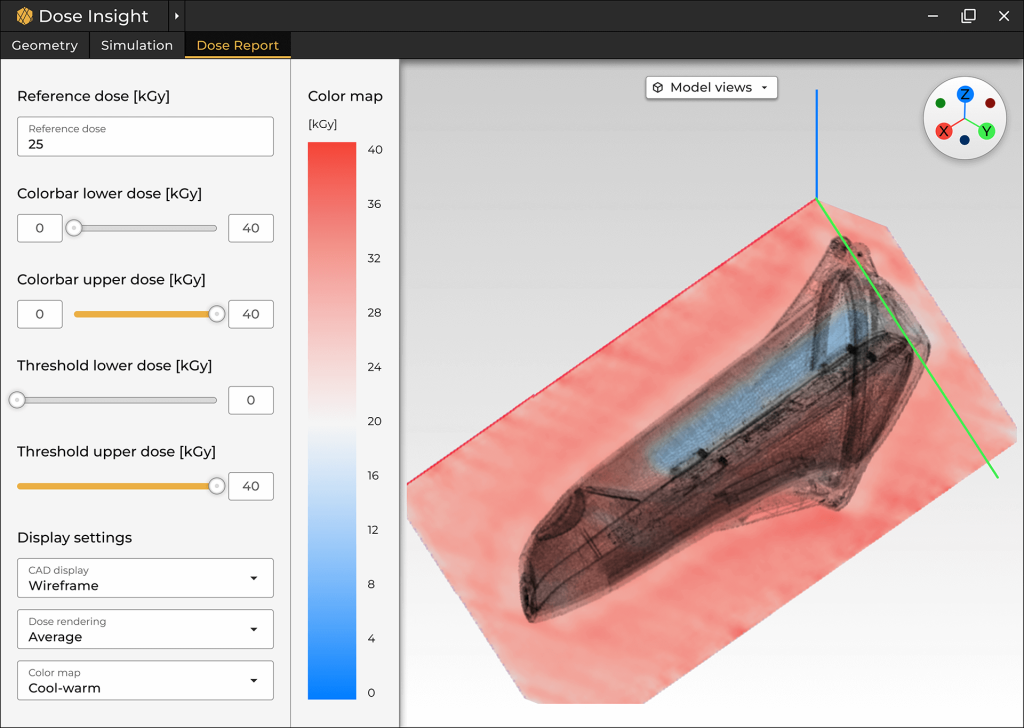

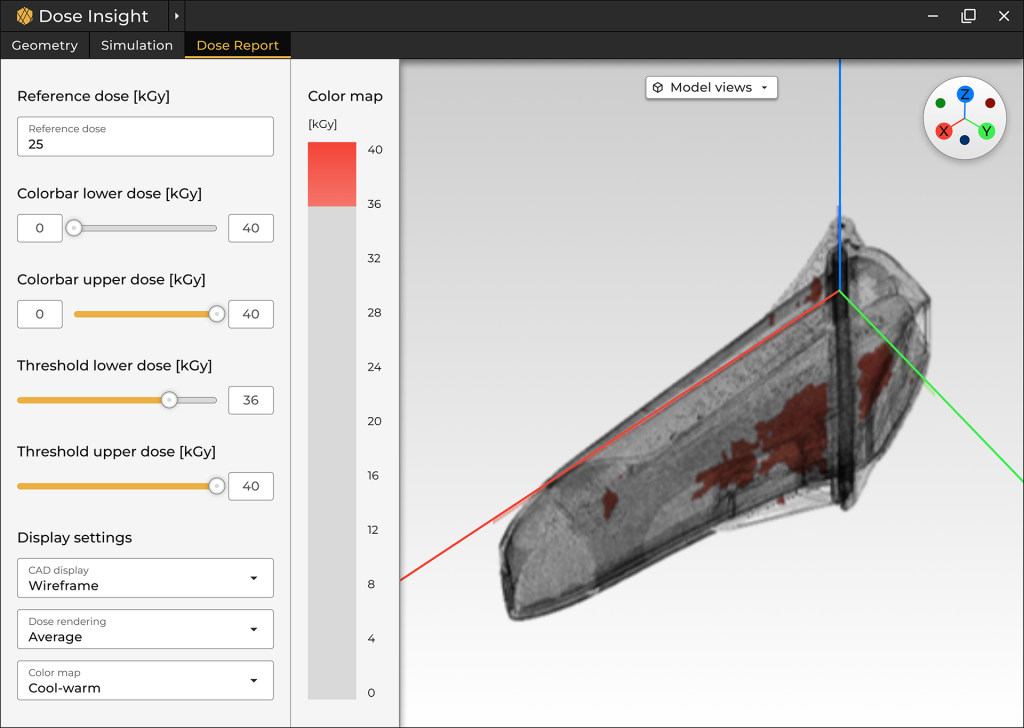

Design for Sterilization (DFS)

Client

Dose Insight

Practice Areas

Challenge

As medical device sterilization validation is most often considered after a device has been fully designed and built, any issues that occur during sterilization result in significant costs and delays. Can computer modeling be used to consider sterilization earlier in the product development process to lower costs and retire risks earlier? Easy-to-use, powerful, and accurate Monte Carlo simulation tools which enable non-expert users to develop medical device sterilization strategies much earlier in the product life cycle.

Outcomes

DFS significantly shortened Medical Device product development cycles and reduced costs through implementation of sterilization strategies early in the design process. It provides precise and accurate radiation dose mapping for complex and sensitive medical devices. Design iteration was enabled without expensive prototyping and costly empirical testing late in product development is eliminated.

Triple Ring Value Proposition

- Deep expertise in complex Monte Carlo simulations

- World-class applied physics capabilities

- GUI design and workflow development expertise

- Experience architecting and implementing scalable cloud infrastructures

- Valuable IP created around virtual dose mapping

Design for Sterilization (DFS)

Challenge

As medical device sterilization validation is most often considered after a device has been fully designed and built, any issues that occur during sterilization result in significant costs and delays. Can computer modeling be used to consider sterilization earlier in the product development process to lower costs and retire risks earlier? Easy-to-use, powerful, and accurate Monte Carlo simulation tools which enable non-expert users to develop medical device sterilization strategies much earlier in the product life cycle.

Outcomes

DFS significantly shortened Medical Device product development cycles and reduced costs through implementation of sterilization strategies early in the design process. It provides precise and accurate radiation dose mapping for complex and sensitive medical devices. Design iteration was enabled without expensive prototyping and costly empirical testing late in product development is eliminated.

Triple Ring Value Proposition

- Deep expertise in complex Monte Carlo simulations

- World-class applied physics capabilities

- GUI design and workflow development expertise

- Experience architecting and implementing scalable cloud infrastructures

- Valuable IP created around virtual dose mapping

Client

Dose Insight

Practice Areas

Background/Approach

With intellectual property developed inside of Triple Ring, Dose Insight’s Monte Carlo simulation tools address serious unmet needs in the Medical Device industry – lowering the cost and time required to build sterilization strategies. Scientists and engineers within Triple Ring have extensively validated the platform across all radiation sterilization technologies and have optimized the tools for use the moment CAD models are established.

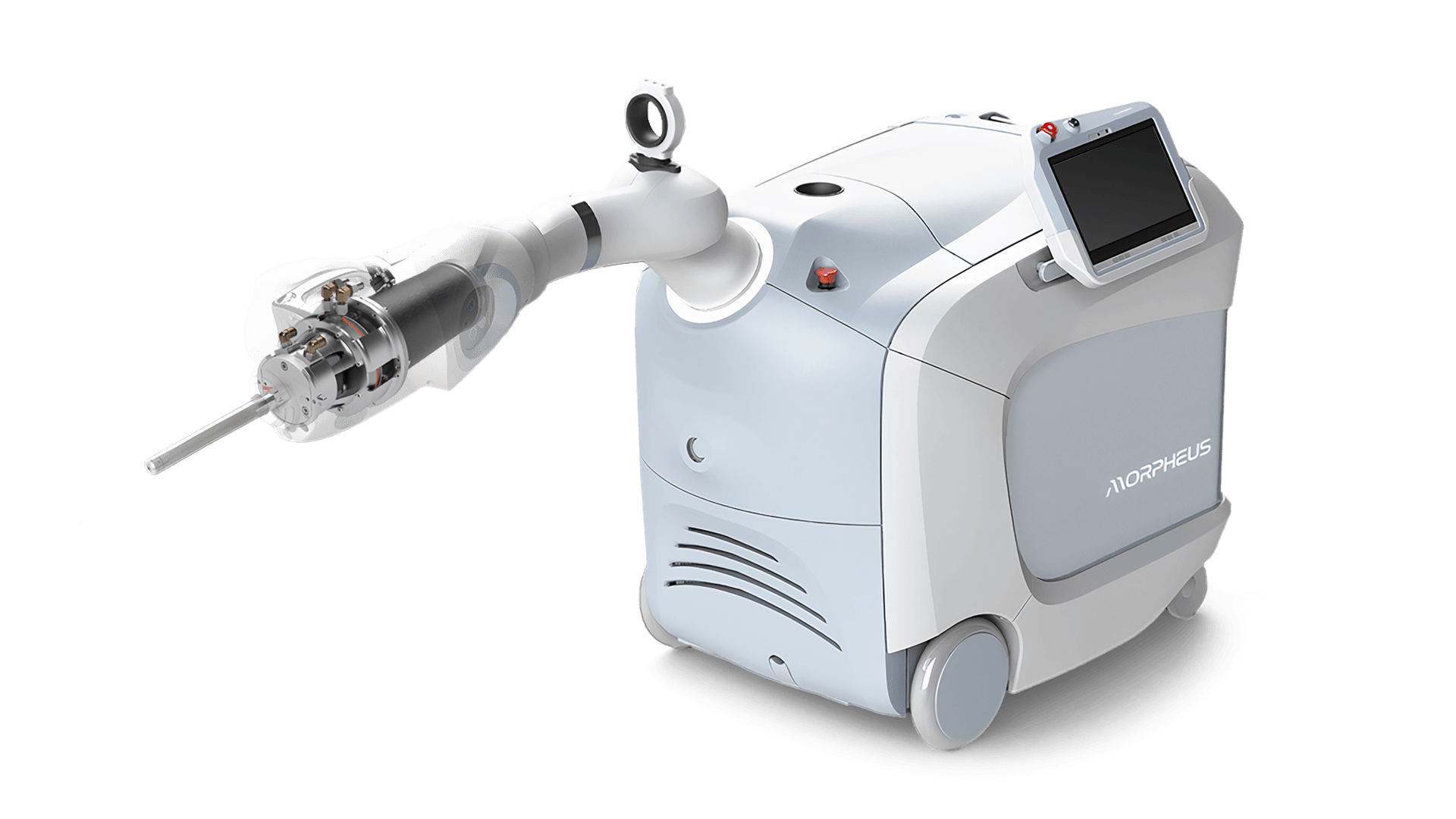

Robotic Radiation Therapy

Client

Empyrean

Practice Areas

Challenge

Triple Ring Technologies designed and developed a novel intra-operative radiation therapy device for Empyrean Medical Systems and facilitated submission of a complete design package to FDA for 510(k) clearance. The compact, mobile, robotically guided, low-energy, intra-operative radiation therapy device was designed with the patient in mind and with a tight focus on useability.

Outcomes

A full system was designed, integrated, verified, clinically validated, and submitted to FDA for marketing clearance. Post 510(k), the device design was transferred to manufacture and launched into the market.

Triple Ring Value Proposition

- Innovative custom x-ray source design for true 3D beam directionality

- Valuable intellectual property created

- Advanced modeling and Monte Carlo simulation to speed design process

- System integration and transfer to manufacture services

- Strong track record of FDA clearance for device designs

Robotic Radiation Therapy

Challenge

Triple Ring Technologies designed and developed a novel intra-operative radiation therapy device for Empyrean Medical Systems and facilitated submission of a complete design package to FDA for 510(k) clearance. The compact, mobile, robotically guided, low-energy, intra-operative radiation therapy device was designed with the patient in mind and with a tight focus on useability.

Outcomes

A full system was designed, integrated, verified, clinically validated, and submitted to FDA for marketing clearance. Post 510(k), the device design was transferred to manufacture and launched into the market.

Triple Ring Value Proposition

- Innovative custom x-ray source design for true 3D beam directionality

- Valuable intellectual property created

- Advanced modeling and Monte Carlo simulation to speed design process

- System integration and transfer to manufacture services

- Strong track record of FDA clearance for device designs

Client

Empyrean

Practice Areas

Background

Empryean Medical and Triple Ring collaborated on the Morpheus System throughout the product development life cycle from concept to market launch. Triple Ring’s contributions included design and development of critical subsystems (x-ray source and beam steering electronics, for examples) to system integration, verification and test, clinical validation, and FDA submission. Triple Ring was chosen as Empyrean’s co-development partner due to our vast experience commercializing complex energy delivery technology for a range of clinical applications.

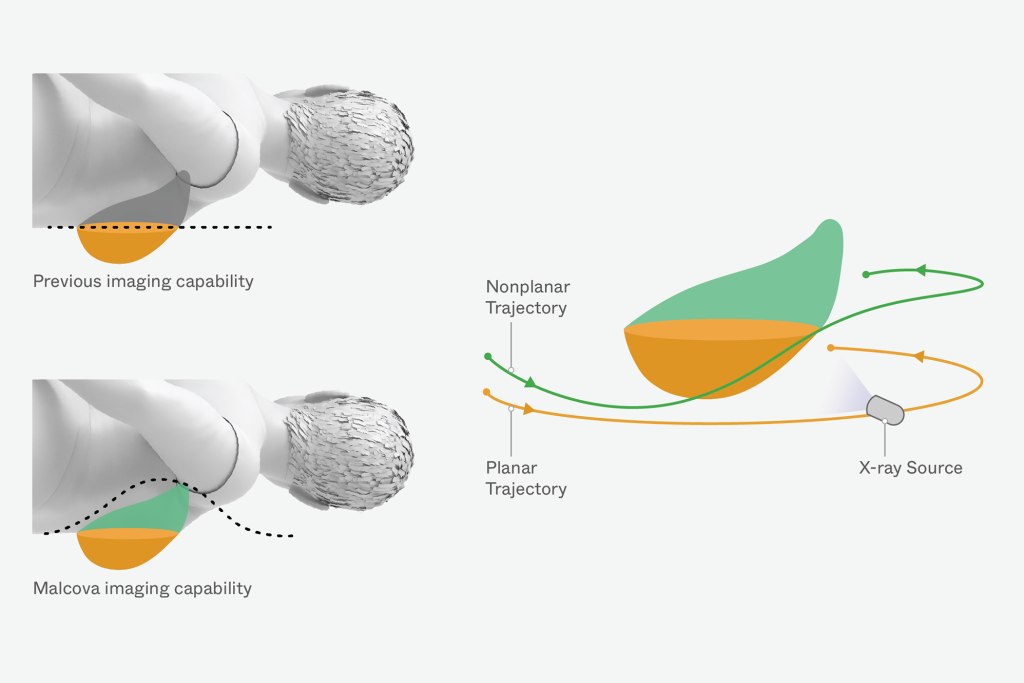

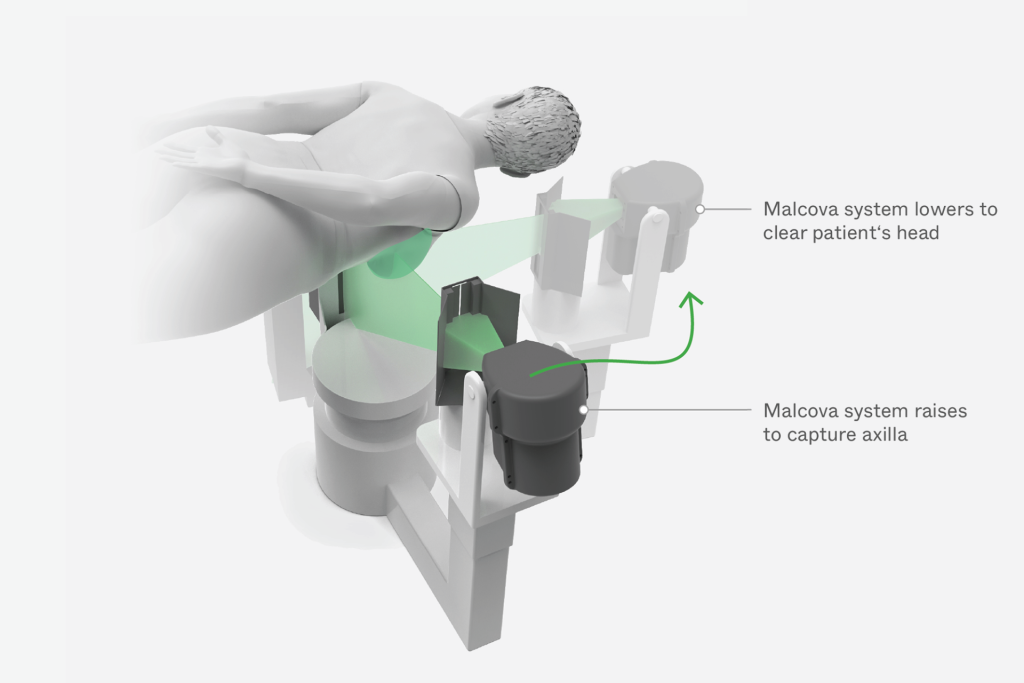

User-Centric Breast Imaging

Client

Malcova

Practice Areas

Challenge

Malcova invented and prototyped a technology to dramatically improve breast imaging while simultaneously improving patient experience. The device featured full 3D imaging capability at ultra-low radiation dose, and expanded coverage of anatomy missed by standard breast CT. The system was designed with the patient in mind and included a workflow that promoted greater comfort and lower stress during procedures. The company’s initial prototype required a complete redesign to support full functionality and ultimately human testing and FDA submission.

Typical CT systems use gantries to control the x-ray source and detector locations in a fixed configuration. Malcova’s system required a gantry-free implementation to achieve 3D imaging, which consequently required independent movement of source and detector. This architecture presented significant synchronization challenges to the production of quality images. Advanced simulations and skillful engineering were required to tackle the challenges inherent in the design. With our deep expertise in advanced robotics and x-ray imaging, Triple Ring was the ideal partner.

Outcomes

Triple Ring designed a CT scanner with the flexibility needed to fully explore the design space of this novel technology.

Value Propositions

- Variable resourced full R&D teams (scientists, engineers, and project managers) available to contribute to the success of an innovative startup

- Deep engineering experience to manage difficult synchronization challenges

- Industry-leading X-ray physics expertise

- Deep experience in Medical Robotics

User-Centric Breast Imaging

Challenge

Malcova invented and prototyped a technology to dramatically improve breast imaging while simultaneously improving patient experience. The device featured full 3D imaging capability at ultra-low radiation dose, and expanded coverage of anatomy missed by standard breast CT. The system was designed with the patient in mind and included a workflow that promoted greater comfort and lower stress during procedures. The company’s initial prototype required a complete redesign to support full functionality and ultimately human testing and FDA submission.

Typical CT systems use gantries to control the x-ray source and detector locations in a fixed configuration. Malcova’s system required a gantry-free implementation to achieve 3D imaging, which consequently required independent movement of source and detector. This architecture presented significant synchronization challenges to the production of quality images. Advanced simulations and skillful engineering were required to tackle the challenges inherent in the design. With our deep expertise in advanced robotics and x-ray imaging, Triple Ring was the ideal partner.

Outcomes

Triple Ring designed a CT scanner with the flexibility needed to fully explore the design space of this novel technology.

Value Propositions

- Variable resourced full R&D teams (scientists, engineers, and project managers) available to contribute to the success of an innovative startup

- Deep engineering experience to manage difficult synchronization challenges

- Industry-leading X-ray physics expertise

- Deep experience in Medical Robotics

Client

Malcova

Practice Areas

Background

Triple Ring has extensive expertise in x-ray imaging and advanced reconstruction technologies in combination with advanced robotics. Triple Ring has designed many dedicated CT systems for both human, animal, and industrial imaging in the last 19 years.

Kuri, the Nimble Companion Robot

Client

Mayfield Robotics

Practice Areas

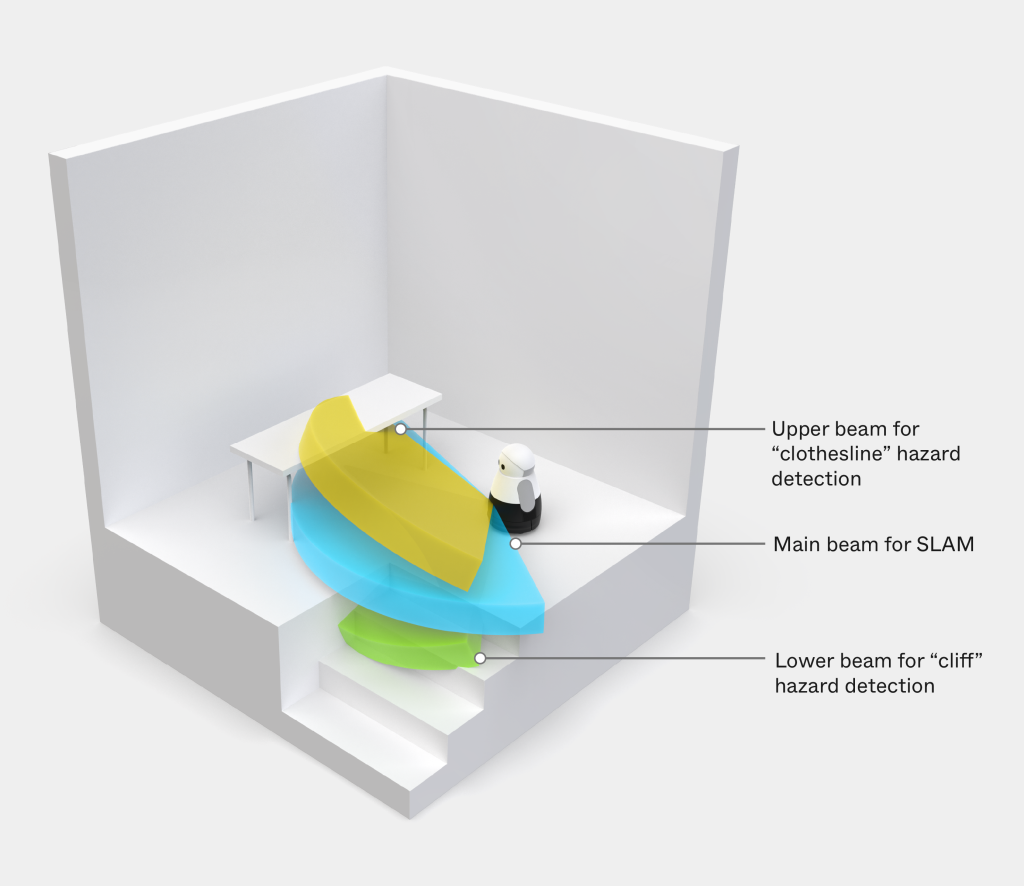

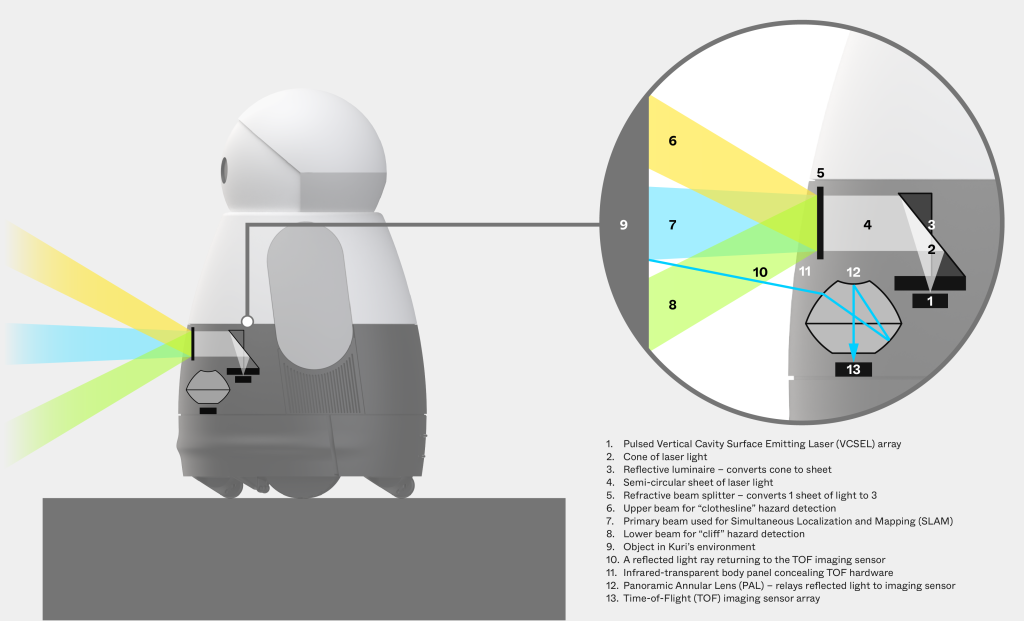

Challenge

Triple Ring technologies was engaged by Mayfield Robotics to design a safe, effective, rugged, and low-cost optical guidance system for home companion robot, called Kuri. Kuri’s optical system needed to perform multiple functions to navigate and interact with her environment, including hazard detection and simultaneous localization and mapping. The integrated guidance optics also needed to be eye-safe for both humans and pets. Triple Ring’s design featured complex optical components, such as a pulsed vertical cavity surface emitting laser array, a panoramic annular lens, and a time-of-flight imaging sensor array.

Outcomes

Triple Ring designed an optical system that exceeded the cost and performance requirements set by the client, most importantly, certification for eye-safety and compliance with UL 3300. Delivering such technology allowed the client, Mayfield Robotics, to successfully launch Kuri as a commercial product and deliver hundreds of units to eager customers. The unique design of Triple Ring’s optical system resulted in 5 pending patents and Kuri being named Best in Show at CES 2017 by PC Magazine, WIRED, and Engadget.

Triple Ring Value Proposition

- Generation of fundamental Intellectual Property translatable to industrial autonomous robotics

- Extensive experience designing exotic and novel optical systems

- System and subsystem level design and integration

- Adherence to aggressive launch schedule to satisfy holiday orders and CES presentation

Kuri, the Nimble Companion Robot

Challenge

Triple Ring technologies was engaged by Mayfield Robotics to design a safe, effective, rugged, and low-cost optical guidance system for home companion robot, called Kuri. Kuri’s optical system needed to perform multiple functions to navigate and interact with her environment, including hazard detection and simultaneous localization and mapping. The integrated guidance optics also needed to be eye-safe for both humans and pets. Triple Ring’s design featured complex optical components, such as a pulsed vertical cavity surface emitting laser array, a panoramic annular lens, and a time-of-flight imaging sensor array.

Outcomes

Triple Ring designed an optical system that exceeded the cost and performance requirements set by the client, most importantly, certification for eye-safety and compliance with UL 3300. Delivering such technology allowed the client, Mayfield Robotics, to successfully launch Kuri as a commercial product and deliver hundreds of units to eager customers. The unique design of Triple Ring’s optical system resulted in 5 pending patents and Kuri being named Best in Show at CES 2017 by PC Magazine, WIRED, and Engadget.

Triple Ring Value Proposition

- Generation of fundamental Intellectual Property translatable to industrial autonomous robotics

- Extensive experience designing exotic and novel optical systems

- System and subsystem level design and integration

- Adherence to aggressive launch schedule to satisfy holiday orders and CES presentation

Client

Mayfield Robotics

Practice Areas

Background

Mayfield Robotics, a subsidiary of a multinational automotive parts manufacturer, sought a unique skill set to design an optical navigation system for integration into Kuri, an at-home companion robot. With industry-leading skills and experience in medical imaging and medical device optics, Triple Ring was the optimal partner. The lessons learned, knowledge gained, and IP generated was transferred to the parent company for integration into navigation subsystems within companion robots built for industrial settings.