User-Centric Breast Imaging

Client

Malcova

Practice Areas

Challenge

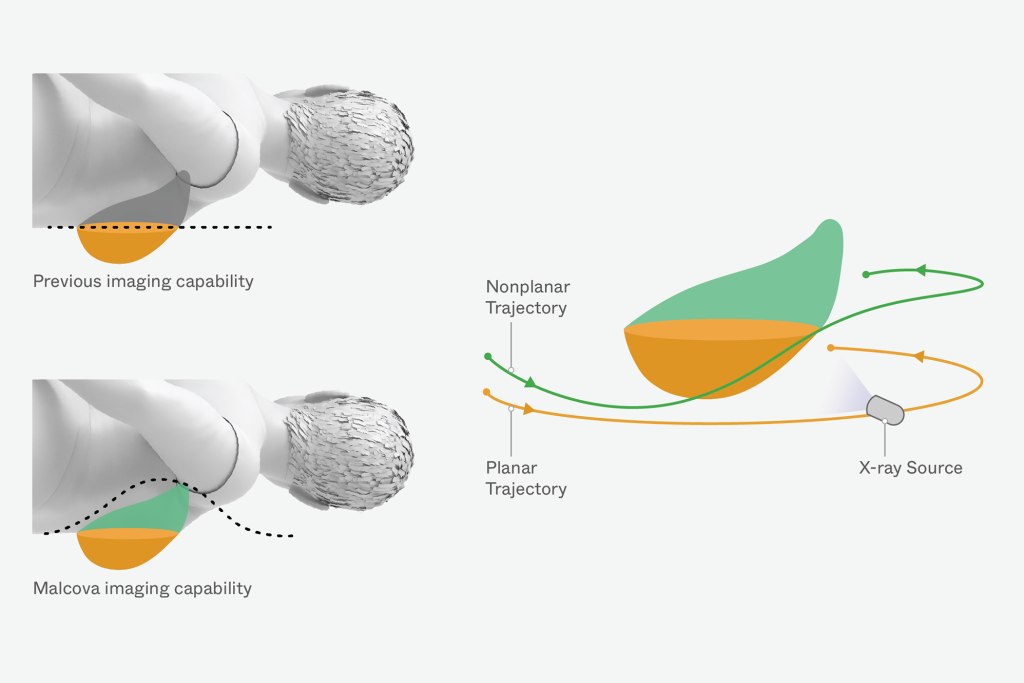

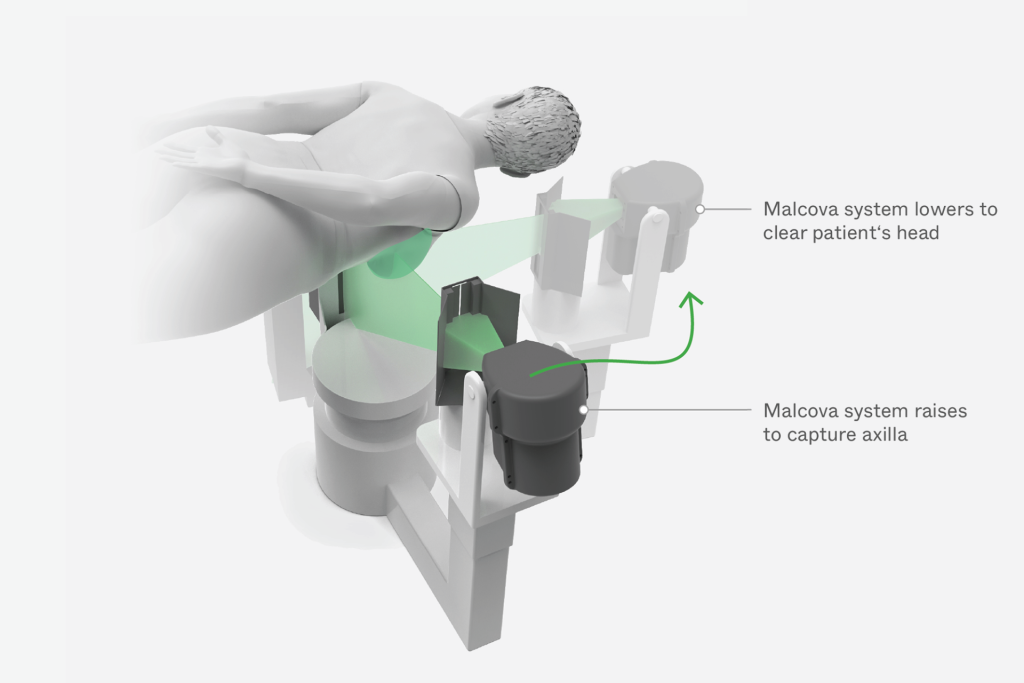

Malcova invented and prototyped a technology to dramatically improve breast imaging while simultaneously improving patient experience. The device featured full 3D imaging capability at ultra-low radiation dose, and expanded coverage of anatomy missed by standard breast CT. The system was designed with the patient in mind and included a workflow that promoted greater comfort and lower stress during procedures. The company’s initial prototype required a complete redesign to support full functionality and ultimately human testing and FDA submission.

Typical CT systems use gantries to control the x-ray source and detector locations in a fixed configuration. Malcova’s system required a gantry-free implementation to achieve 3D imaging, which consequently required independent movement of source and detector. This architecture presented significant synchronization challenges to the production of quality images. Advanced simulations and skillful engineering were required to tackle the challenges inherent in the design. With our deep expertise in advanced robotics and x-ray imaging, Triple Ring was the ideal partner.

Outcomes

Triple Ring designed a CT scanner with the flexibility needed to fully explore the design space of this novel technology.

Value Propositions

- Variable resourced full R&D teams (scientists, engineers, and project managers) available to contribute to the success of an innovative startup

- Deep engineering experience to manage difficult synchronization challenges

- Industry-leading X-ray physics expertise

- Deep experience in Medical Robotics

User-Centric Breast Imaging

Challenge

Malcova invented and prototyped a technology to dramatically improve breast imaging while simultaneously improving patient experience. The device featured full 3D imaging capability at ultra-low radiation dose, and expanded coverage of anatomy missed by standard breast CT. The system was designed with the patient in mind and included a workflow that promoted greater comfort and lower stress during procedures. The company’s initial prototype required a complete redesign to support full functionality and ultimately human testing and FDA submission.

Typical CT systems use gantries to control the x-ray source and detector locations in a fixed configuration. Malcova’s system required a gantry-free implementation to achieve 3D imaging, which consequently required independent movement of source and detector. This architecture presented significant synchronization challenges to the production of quality images. Advanced simulations and skillful engineering were required to tackle the challenges inherent in the design. With our deep expertise in advanced robotics and x-ray imaging, Triple Ring was the ideal partner.

Outcomes

Triple Ring designed a CT scanner with the flexibility needed to fully explore the design space of this novel technology.

Value Propositions

- Variable resourced full R&D teams (scientists, engineers, and project managers) available to contribute to the success of an innovative startup

- Deep engineering experience to manage difficult synchronization challenges

- Industry-leading X-ray physics expertise

- Deep experience in Medical Robotics

Client

Malcova

Practice Areas

Background

Triple Ring has extensive expertise in x-ray imaging and advanced reconstruction technologies in combination with advanced robotics. Triple Ring has designed many dedicated CT systems for both human, animal, and industrial imaging in the last 19 years.

Microneedle Patch Applicator

Client

Confidential

Practice Areas

Challenge

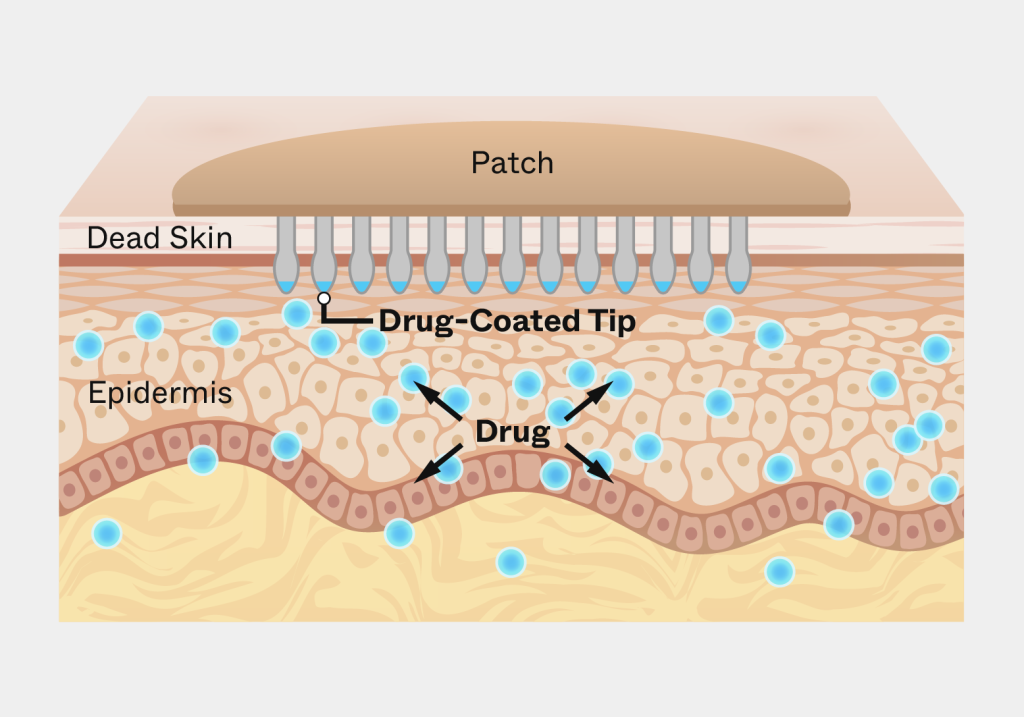

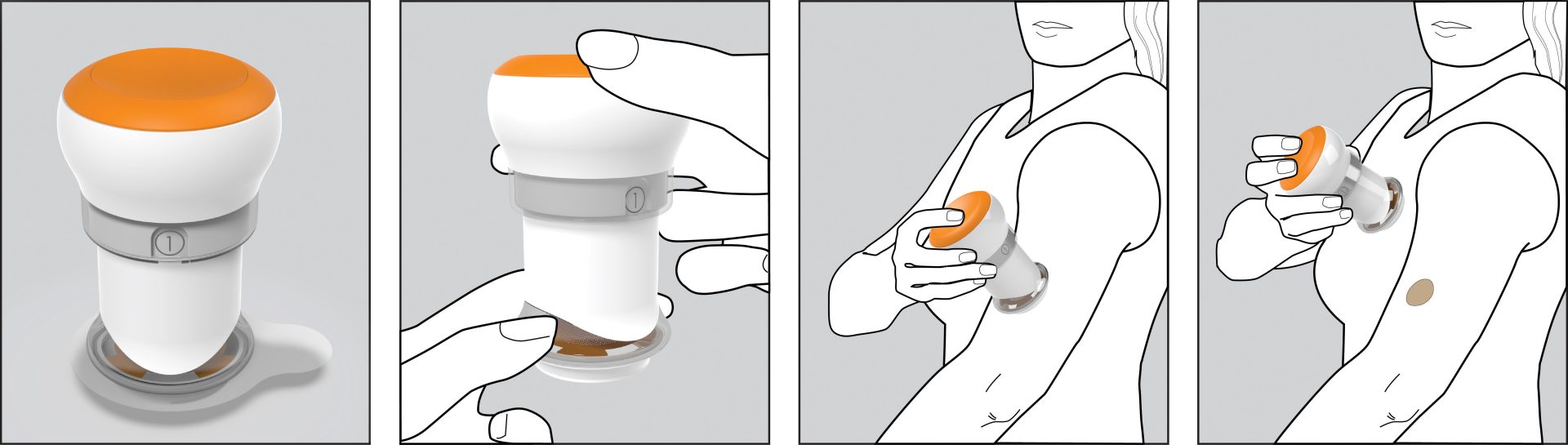

The client had developed a novel microneedle patch for transdermal drug delivery intended for use by the patient at home. The patch required a significantly greater degree of uniformity in pressure during application than existing transdermal patches. It required design of a reusable applicator to achieve reliable adhesion and dosing, while supporting the robustness and ruggedness requirements for use by a patient in their home and a low cost.

The key was ensuring that the patch would work across a wide variety of skin types in the potential patient population. Triple Ring relied on its expertise in material design and selection, precision mechanical engineering, and our life scientists to design an applicator that provided the required pressure for patch adhesion, across skin types that varied by thickness, age, moisture content, and placement.

Outcomes

The resulting single-entity combination product comprised a reusable applicator and a microneedle array containing patch, for intracutaneous drug delivery allowing rapid absorption into the bloodstream. With the applicator, the client was able to successfully enter clinical trials. Ultimately the technology for the product was acquired by a vaccine manufacturer.

Value Propositions

Triple Ring’s interdisciplinary team had all the required skills for a complex design.

Microneedle Patch Applicator

Challenge

The client had developed a novel microneedle patch for transdermal drug delivery intended for use by the patient at home. The patch required a significantly greater degree of uniformity in pressure during application than existing transdermal patches. It required design of a reusable applicator to achieve reliable adhesion and dosing, while supporting the robustness and ruggedness requirements for use by a patient in their home and a low cost.

The key was ensuring that the patch would work across a wide variety of skin types in the potential patient population. Triple Ring relied on its expertise in material design and selection, precision mechanical engineering, and our life scientists to design an applicator that provided the required pressure for patch adhesion, across skin types that varied by thickness, age, moisture content, and placement.

Outcomes

The resulting single-entity combination product comprised a reusable applicator and a microneedle array containing patch, for intracutaneous drug delivery allowing rapid absorption into the bloodstream. With the applicator, the client was able to successfully enter clinical trials. Ultimately the technology for the product was acquired by a vaccine manufacturer.

Value Propositions

Triple Ring’s interdisciplinary team had all the required skills for a complex design.

Client

Confidential

Practice Areas

Background

The client was a publicly traded company with deep medical and domain expertise to address a drug delivery problem using their novel patch technology. They selected Triple Ring to design the mechanical delivery device based upon our long history of working with designing novel technologies for health care that delivered excellent user experiences. The Triple Ring designed applicator allowed the client to both more easily demonstrate their technology to other health care professionals and to get it into the hands of end users in clinical trials.

IVD Platform Refresh

Client

Fortune 500 IVD Company

Practice Areas

Challenge

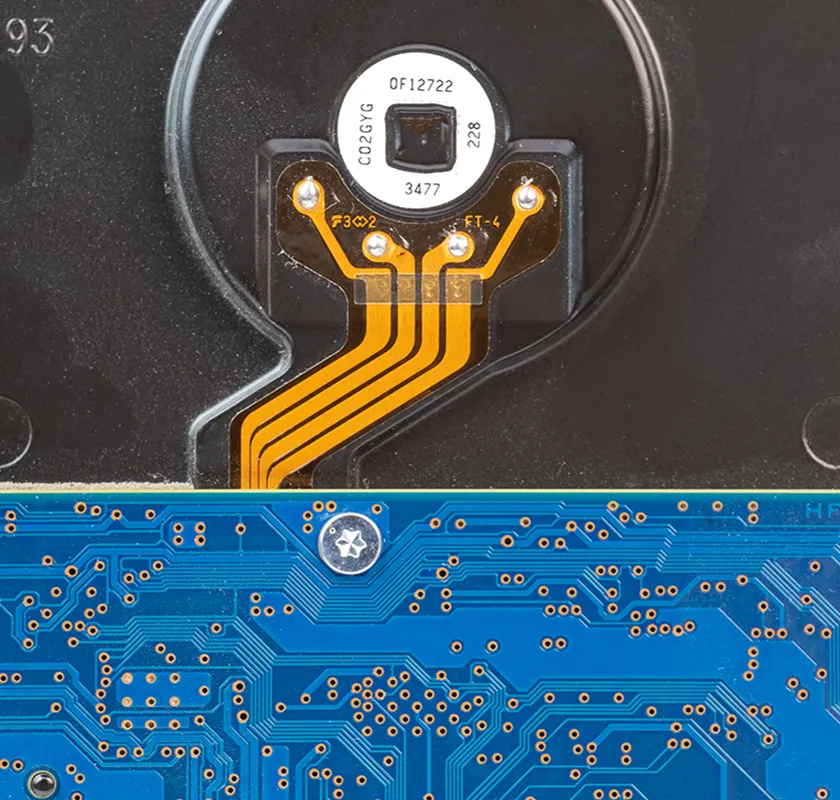

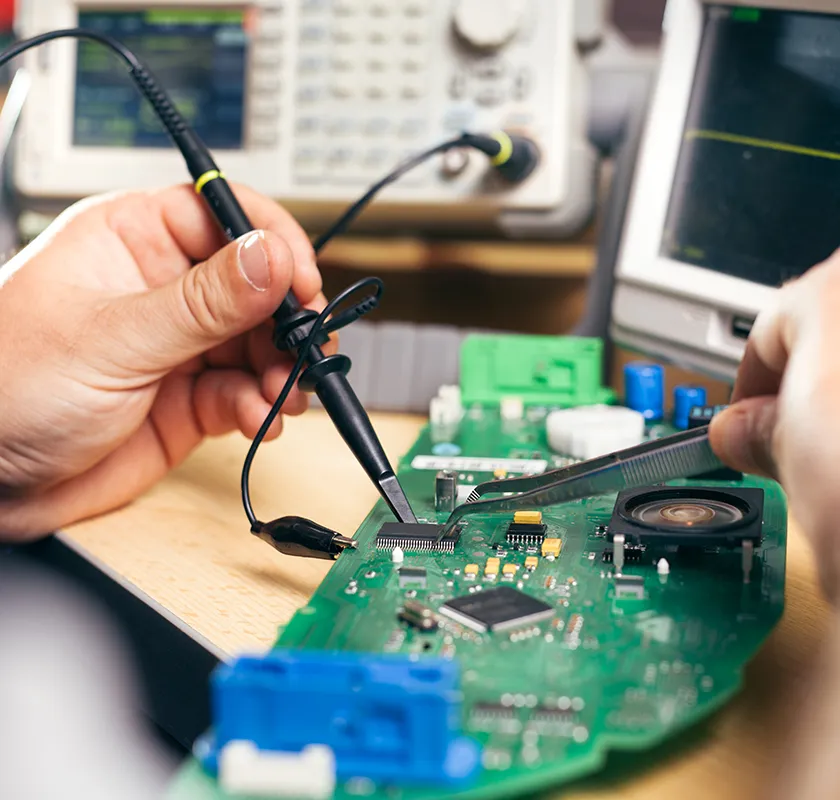

Our client faced the obsolescence of critical components within a legacy IVD product platform, including single-board computers and microcontrollers. A lack of original firmware source code and the sunsetting of institutional knowledge required extensive reverse engineering before updates could be designed and implemented. Adding further complexity, Triple Ring was tasked with modernizing the product to maintain market competitiveness yet demonstrate equivalence to fulfill the criteria of a Special 510(k) regulatory pathway.

Outcomes

A full system design and regulatory package was delivered for a refreshed IVD product with demonstrated equivalency to its FDA-cleared predecessor. Triple Ring replaced obsolete components, reverse-engineered and migrated existing software to a new OS, updated subassemblies, and developed new firmware compatible with legacy systems. The refreshed system featured modern industrial design, met manufacturing cost targets, and integrated seamlessly with existing manufacturing processes, ensuring uninterrupted production.

Value Propositions

- Multidisciplinary teams skilled in reverse engineering and future-proofing

- Software porting expertise

- In-depth knowledge of clinical IVD devices and relevant regulatory requirements

- Strong collaboration with client manufacturing and service teams

- Industrial Design capabilities to modernize user experience

IVD Platform Refresh

Challenge

Our client faced the obsolescence of critical components within a legacy IVD product platform, including single-board computers and microcontrollers. A lack of original firmware source code and the sunsetting of institutional knowledge required extensive reverse engineering before updates could be designed and implemented. Adding further complexity, Triple Ring was tasked with modernizing the product to maintain market competitiveness yet demonstrate equivalence to fulfill the criteria of a Special 510(k) regulatory pathway.

Outcomes

A full system design and regulatory package was delivered for a refreshed IVD product with demonstrated equivalency to its FDA-cleared predecessor. Triple Ring replaced obsolete components, reverse-engineered and migrated existing software to a new OS, updated subassemblies, and developed new firmware compatible with legacy systems. The refreshed system featured modern industrial design, met manufacturing cost targets, and integrated seamlessly with existing manufacturing processes, ensuring uninterrupted production.

Value Propositions

- Multidisciplinary teams skilled in reverse engineering and future-proofing

- Software porting expertise

- In-depth knowledge of clinical IVD devices and relevant regulatory requirements

- Strong collaboration with client manufacturing and service teams

- Industrial Design capabilities to modernize user experience

Client

Fortune 500 IVD Company

Practice Areas

Background

A large multinational corporation specializing in In Vitro Diagnostic (IVD) devices engaged with Triple Ring to refresh and future-proof a legacy product line facing component and software obsolescence. Triple Ring executed an accelerated program to modernize the platform while holding production costs steady and demonstrating equivalent performance.

Maximize Legacy Product Value

Client

Large Corporations

Practice Areas

Background

Sustaining engineering is more than product maintenance and implementing market requests; it’s a strategic approach to keeping legacy products competitive and profitable over decades. At Triple Ring, we don’t simply maintain legacy products – we transform them to meet modern demands. We add high-value features like AI in addition to updating industrial design, increasing reliability, and lowering production costs. We also address evolving regulatory risk, including cyber security, while carefully protecting core intellectual property.

Modernization of Legacy Products

Keeping products ahead in the market through:

- AI design and integration

- Cybersecurity software migrations

- Performance upgrades and added functionality

- Refreshed industrial design, usability, and aesthetics

- Supply chain security

Maximize Legacy Product Value

Background

Sustaining engineering is more than product maintenance and implementing market requests; it’s a strategic approach to keeping legacy products competitive and profitable over decades. At Triple Ring, we don’t simply maintain legacy products – we transform them to meet modern demands. We add high-value features like AI in addition to updating industrial design, increasing reliability, and lowering production costs. We also address evolving regulatory risk, including cyber security, while carefully protecting core intellectual property.

Modernization of Legacy Products

Keeping products ahead in the market through:

- AI design and integration

- Cybersecurity software migrations

- Performance upgrades and added functionality

- Refreshed industrial design, usability, and aesthetics

- Supply chain security

Client

Large Corporations

AI Enhancement

Enhancing legacy systems with physics-based AI improves performance, accuracy, and efficiency, and supports predictive maintenance. These features dramatically extend product lifespan without costly hardware upgrades. Triple Ring has the experience and expertise in AI algorithm design and integration to modernize products and create new valuable solutions for customers.

Supply Chain Optimization

Updating and optimizing supply chains addresses obsolescence, reduces cost, increases production yields and product reliability. Triple Ring and our partners ensure smooth production, minimize disruptions, and unlock new cost-saving opportunities for your legacy products.

Why Partner with Triple Ring?

Successful products often outlive the teams that launched them resulting in critical knowledge gaps within organizations that grow over time. Product companies need a trusted partner with deep expertise in reverse engineering, modern regulatory standards, supply chain access, and expertise in AI. Partnering with Triple ring unlocks these benefits, and importantly, saves product companies the cost and schedule delays associated with rebuilding engineering teams. Ensure product success and optimal return on investment over the long haul by engaging with Triple Ring on your next sustaining engineering project.